Model Predictive Control¶

Three workflows utilize advanced control based on Model Predictive Control (MPC) under the hood. MPC is an optimization approach that considers operational aspects over a time horizon. These workflows are briefly described below, whereas more background information on the algorithms used can be found here: MPC Background Information

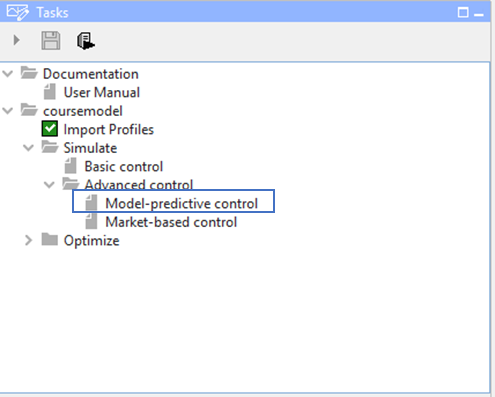

Simulate -> Advanced Control -> MPC: The objective of this workflow is to find a more cost-effective operational actuation in an automated manner, compared to rule-based control that requires the user to define a merit order. So it is a posteriori allocation of sources as a result of the simulation versus a priori merit order. The MPC optimizes the actuation once for the entire simulation time and uses these outcomes to actuate CHESS with power allocations. The MPC optimizes to minimize operational costs. For example, in the case of equal variable operational costs for all sources, the optimization will try to minimize heat losses and thereby the supply temperature.

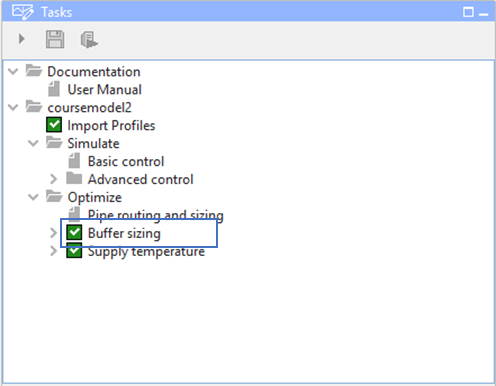

Optimize -> Buffer Sizing: The objective of this workflow is to find the smallest suitable buffer size. Application include scenarios where the user wants to outphase a back-bone heat supply or maximize the use of a baseload source in combination with storage. The user can select a maximum size of the buffer, production priorities and some hydraulic constraints. The priorities (1 representing the most favored source) are used by the optimization to maximize the allocation of more favored sources, in combination with the buffer. Note that this workflow assumes constant temperatures for the optimization. For details on this constant-temperature approach, see the HeatMixin class in the RTC-Tools Heat Network documentation.

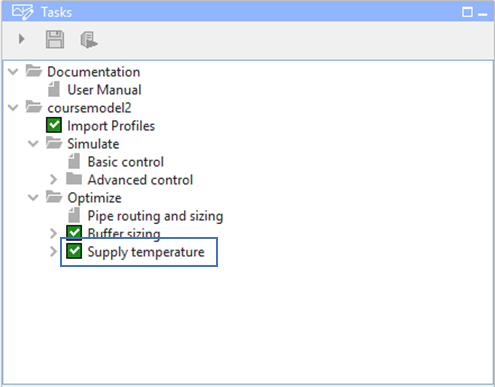

Optimize -> Supply temperature: The objective of this workflow is to assess the minimum supply temperature in the network whilst still meeting heat demand. This workflow can be used to see whether low temperature heat sources (e.g. aquathermal, data centers, etc. ) are suitable. The optimization will try to maximize the flow velocities whilst meeting required minimum supply temperature and staying within hydraulic limits. The optimization process is equivalent to the Simulate -> Advanced Control -> MPC workflow, however here CHESS is not ran after the MPC. This means that the results are solely based on the internal model of the MPC. This increases the computational speed of the workflow, however MPC has a slightly lower fidelity model compared to CHESS.

RTC-Tools-heat-network FrameWork The MPC workflows utilize a self-developed MPC framework called “rtc-tools-heat-network”. This software repository can be installed as a python package and allows to make a MPC application for heat networks. It contains heat network physics, parsing of ESDL files to an internal model and an optimization approach called goal programming. Rtc-tools-heat-network can be used to define a workflow with appropriate optimization goals and the heat network dynamics of interest.

RTC-tools-heat-network Documentation explains the theoretical optimization approach, implemented physics and how to use the API. This documentation is meant for the advanced user that has a specific need and therefore implements its own workflow.